Spark & Gas Protection

Sparks can ignite a fire or cause an explosion in certain environments so it’s important to minimise the risks of activities such as welding, burning and grinding, particularly if they are taking place in a factory or site that is still operational, or an area where oil, gas and other flammable substances are stored in close proximity. We design unique protective covers that minimise the risks of working in such environments. Our solutions can minimise or eliminate downtime, and the high costs associated with a site being out of operation for maintenance work to take place.

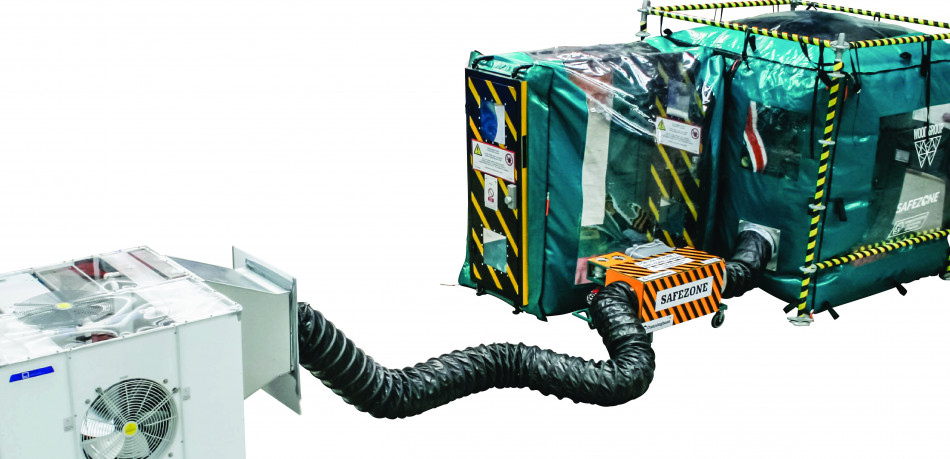

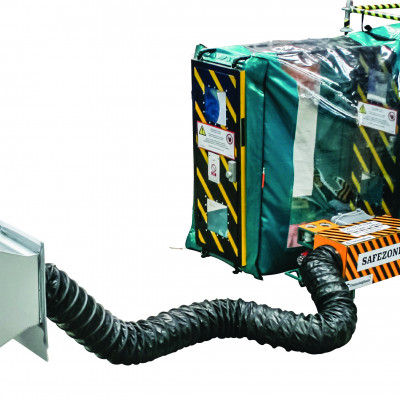

At Cunningham Covers, we have a designed a moveable enclosure known as Safezone which houses workers and allows them to perform hot work in isolation without the need to shut down all other operations. The Safezone enclosure is placed in the area where welding, burning and grinding activities need to take place, effectively creating a barrier between the area of work, and the rest of the plant. This unique covering is portable, light but durable to reduce the risk of rips and tears, heat resistant, water resistant and a safe environment for workers (Safety Integrity Level 2 rated). It’s also cost-effective to transport, quick and easy to set-up, re-usable and works extremely well in even the most demanding and harsh environments.

Manufactured in the UK. Shipped Globally. Clever protective covers.

Oil & Gas • North Sea

Bespoke Flame Retardant Tarps, Blankets and Anti-Static Covers

View full case study

Do you need a clever protective cover?

Talk to our Technical Team today

For further technical details and individual project guidance, give us a ring on the number below or fill out our enquiry form.

We look forward to speaking to you!

0044 2879 444 339

0044 2879 444 339Offices Open

8am - 5pm GMT

Monday - Friday

Ask an expert

Our technical team will receive your request

instantly and respond to your request.